主要性能参数

公称通径:DN50-DN600mm

压力范围:1.0、1.6Mpa

介质温度:-20℃-400℃

阀体材料:WCB、304、316

功能选项:开关、调节、防爆

技术规范

| 设计依据 Design reference | GB标准 | ANS标准 |

| 设计标准 Design standard | GB/12237 | ANSI B16.34 |

| 结构长度 Face To face | 对夹式连接 Wafer Type connecting | GB/1221 | ANSI B16.10 |

| 连接法兰尺寸 Connecting Flange Size | GB/9113、JB/T79 | ANSI B16.5 |

| 试验和检验 Test & insoection | JB/T9002 | API 598 |

*注:系列球阀结构长度及连接法兰尺寸可根据用户要求设计制造

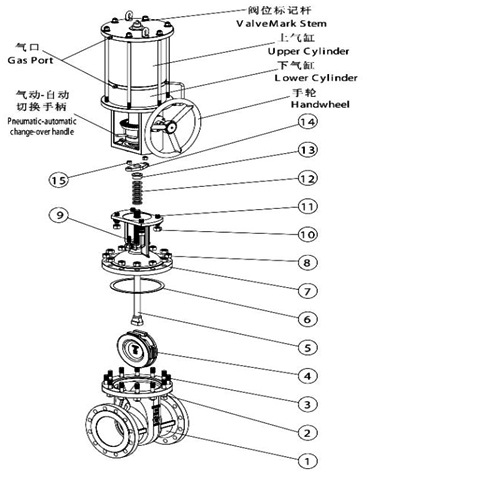

主要零件材质表

| 序号 No | 零件名称 Accessory name | 材质 |

| C | P | R |

| 1 | 阀体Body | WCB | ZG1Cr18Ni9Ti | 1Cr18Ni12Mo2T |

| 2 | 螺帽Screw Cap | 35 | 1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 3 | 螺栓Bolt | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 4 | 闸板Shut-off Device | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 5 | 阀杆Stem | 1Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 6 | 垫片Gasket | 不锈钢+柔性石墨 Stainless Steel+Graphite | 不锈钢+柔性石墨 Stainless Steel+Graphite | 不锈钢+柔性石墨 Stainless Steel+Graphite |

| 7 | 阀盖Cover | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 8 | 螺帽Screw Cap | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 9 | 吊环螺栓 Lifting Ring Bolt | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 10 | 螺帽Screw Cap | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 11 | 螺栓Bolt | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 12 | 填料Packing | 柔性石墨 Graphite | 柔性石墨 Graphite | 柔性石墨 Graphite |

| 13 | 填料压套 Packing Gland | WCB | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 14 | 填料压板 Packing Plate | WCB | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 15 | 螺帽Screw Cap | 35 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

*注:主要零部件及密封圈的材质亦可根据实际工况条件或用户特殊要求设计选用.

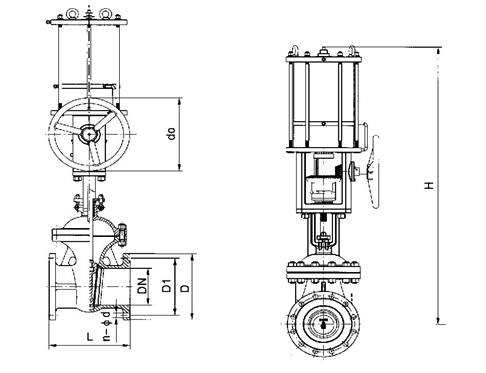

主要外形及连接法兰尺寸

| 公称通径 DN Nominalsiza | 外形尺寸 Outline Size |

| GB标准外形及连接尺寸(PN1.0Mpa) Outline and Connecting Size to GB Standard (PN1.0Mpa) | ANSI标准外形及连接尺寸(Class150) Outline and Connecting Size to ANSI Standard (Class150) |

| L | H | D | D1 | n-φd | L | H | D | D1 | n-φd |

| 50 | 60 | 335 | 165 | 125 | 2-18 2-M16 | 48 | 335 | 152 | 120.5 | 2-19 2-M16 |

| 65 | 60 | 363 | 185 | 145 | 2-18 2-M16 | 48 | 363 | 178 | 139.5 | 2-19 2-M16 |

| 80 | 60 | 395 | 200 | 160 | 2-18 2-M16 | 50 | 395 | 190 | 152.5 | 2-19 2-M16 |

| 100 | 60 | 465 | 220 | 180 | 6-18 2-M16 | 50 | 465 | 229 | 190.5 | 6-19 2-M16 |

| 125 | 60 | 530 | 250 | 210 | 6-18 2-M16 | 57 | 530 | 254 | 216 | 6-22 2-M20 |

| 150 | 70 | 630 | 285 | 240 | 6-23 2-M20 | 57 | 630 | 279 | 241.5 | 6-22 2-M20 |

| 200 | 80 | 750 | 340 | 295 | 6-23 2-M20 | 70 | 750 | 343 | 298.5 | 6-22 2-M20 |

| 250 | 86 | 900 | 395 | 350 | 8-23 4-M20 | 70 | 900 | 406 | 362 | 8-25 4-M22 |

| 300 | 92 | 1120 | 445 | 400 | 8-23 4-M20 | 76 | 1120 | 483 | 432 | 8-25 4-M22 |

| 350 | 100 | 1260 | 505 | 460 | 10-23 6-M20 | 76 | 1260 | 533 | 476 | 18-29 4-M27 |

| 400 | 120 | 1450 | 565 | 515 | 10-25 6-M22 | 89 | 1450 | 597 | 540 | 12-29 4-M27 |

| 450 | 125 | 1600 | 615 | 565 | 14-25 6-M22 | 89 | 1600 | 635 | 578 | 12-32 4-M30 |

| 500 | 130 | 1800 | 670 | 620 | 14-25 6-M22 | 114 | 1800 | 699 | 635 | 14-32 6-M30 |

| 600 | 130 | 2300 | 780 | 725 | 14-30 6-M27 | 114 | 2300 | 813 | 749.5 | 14-35 6-M33 |

| 700 | | | | | | | | | | |

| 800 | | | | | | | | | | |